Fundamentals of LPG Bottling Plant Operations: Machinery and Sequence

Ashok Khopkar

View profile

Language

504 Views

2 Enrollments

Share

Access anytime

80 Min

This course format through pre-recorded video. You can buy and watch it to learn at any time.

₹ 99

videos

₹ 99

Why do you enroll

Key topics covered

Course details

Course tags

Course content

Why do you enroll

Take the first step towards a rewarding career in the energy sector with our introductory course on LPG Bottling Plant Operation Sequence and Machinery Used. This foundational knowledge will equip you with a comprehensive understanding of the equipment, processes, and safety protocols involved in LPG bottling plant operations. As you progress in your career, you'll be well-positioned to take on roles such as Plant Operator, Maintenance Supervisor, or Quality Control Specialist, with opportunities for advancement to senior leadership positions. With this course, you'll gain a competitive edge in the industry and be poised for long-term success in this dynamic and in-demand field.

Show more

Key topics covered

1. Why filling by weight,

2. How much gas to fill --- filling density concept

3. Commonly used terminology

4. Operation sequence

5. Machinery used for various operations

Show more

Course Details

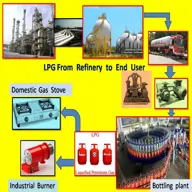

Objective: To explain the "Filling by weight" principle used for LPG cylinder filling (Bottling) process, the operations carried out , the sequence and the machinery used for that. It is a long line of machines, performing a particular function, essential for safe filling operation and subsequent storage of cylinders; and at end user's place.

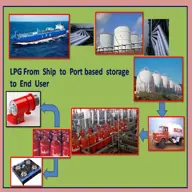

Subject description: As domestic fuel, LPG is efficient, clean and convenient. Millions of household have a cylinder in their house. Thousands of cylinders are filled every hour, 24x7. As such, LPG bottling operations are truly mass production process.

LPG is a gas, liquefied by pressuring, for storage, filling and transportation. It is highly inflammable, needing only 1.8% concentration in mixture with air, to make it ignitable. It changes from liquid state to gaseous state if pressure is reduced. This phenomenon creates serious problems throughout the filling process.

Filling process involves filling precise quantity of LPG liquid into cylinder. Underfilling is not permitted legally whereas Overfilling is hazardous. The tolerance band is narrow. It is interesting to see 'How it is managed, how it is checked, how leakages are detected'.

This introductory course is an attempt to answer these questions. For those who are associated with bottling plants and those wish to work in that field, it is essential to understand the complete sequence of processes. A wide spectrum of machinery --manual to fully automatic -- is used in these plants. Each involves setting changes to fill various capacities of cylinders.

Remember, it's matter of safety of millions of houses, which cannot be jeopardised because of lack of knowledge. Basic Knowledge of complete process, machinery used and operation will help in enhancing safety, taking higher responsibility; leading to higher position in organisation / higher remuneration and progress.

It is essential to have sufficient knowledge about LPG also. So it is advisable to acquire that along with knowledge of bottling process.

Who must attend this course and other courses?

1. Professionals already working with LPG bottling industry, and related industry

2. LPG cylinder distributors, and other service providers

3. Professionals looking for working in highly complex, exciting and ever expanding engineering field

4. Newcomers in LPG industry

5.. Job seekers having aptitude for technical jobs, with school level education, engineering diploma or degree, engineering college students

Show more

Course tags

Industry domains :

Engineering Disciplines :

Course content

1

Introduction of LPG Bottling :

2

LPG Terminology :

3

Why LPG weight basis? :

Show more

FAQs on Fundamentals of LPG Bottling Plant Operations: Machinery and Sequence

Having specific question ? Ask now

Trainer’s Feedback

1 course rating

1 ratings

SD

Shubham Deep

20 days ago

VIDEO LINK IS NOT ABLE TO OPEN

Certificate of Mastery

Receive well recognised certificate that you can showcase on

Featured courses

Hazard Identification and Risk Assessmen...

How to prevent corrosion in the oil and ...

Application and use of "Green Hydrogen"

Career in EPC projects for Freshers

Career in EPC Cost Estimation

Learn MATLAB Programming

More Technical Courses From Ashok Khopkar

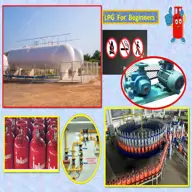

LPG Basics - Specialised course for Begi...

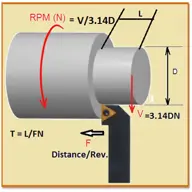

Estimation of machining time for Lathe ...

Estimation of machining time for Milling...

What is LPG - Know More Closely

Understanding on Product costing - From ...

Understanding about Measuring units used...

Safety during transporting bulk LPG by r...

Spotlight on Safety features in LPG stor...

More Articles From Ashok Khopkar

"LPG for Beginners" Series of articles ...

“LPG for Beginners” Series of Articles ...

Machining Time Calculation

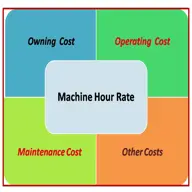

Machine Hour rate Calculation

“LPG FOR BEGINNERS” Series of Articles ...

“LPG for beginners" Series of article...

“LPG for Beginners” Serie...

"LPG for Beginners" Series of articles...

"LPG for Beginners" Series of articles...

More Communities From Ashok Khopkar

Similar Content Learn:

Different element types commonly used in...

Solidworks Advanced

CMS IntelliCAD Advanced 2D

CMS IntelliCAD Intermediate 2D

CMS IntelliCAD Basic 2D

Hydraulic System Basic & Machine Design.

Similar Content Mentor:

All About Interviews

Presentation Skills _ Part 2

How to motivate & encourage team bonding...

Time Management essentials for Engineers...

COMMUNICATE TO WIN - The most important ...

Similar Content Seminar:

The Petrochemical and Refining Congress:...

The Oil and Gas Decarbonisation Congress...

OIL & GAS AUTOMATION AND DIGITALISATION ...

7th International Oil & Gas Chemistry, C...

Similar Content Blogs:

Reaching Net-Zero: The Power of Predicti...

Types of Piping Valves for Oil and Gas I...

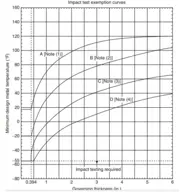

Technical Basis for Impact Test Exemptio...

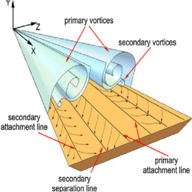

Aerodynamic physics of the Delta Wing

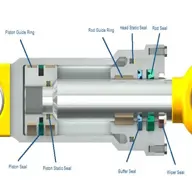

Seal of Hydraulic cylinder.

PRC Europe 2025: Italian Partners at the...

Similar Content Community:

Firefighting Design By Naga

Engineer's Corner

Cathodic protection

Corrosion

Cae engineers

Similar Profile:

Hira Lal

Engineer

Vijay Sachdev

Consultant - Project & Pr...

Sabari Kuppuraj

Engineer

Mir Abbas

Senior Engineer

Anup Kumar Dey

Owner of https://whatispi...

Jyoti Swarup

--

Praveen Tiwari

--

Please wait