Estimation of machining time for Lathe machine operations

Ashok Khopkar

View profile

1013 Views

Share

-

-

-

This course format is where trainer will explain you the subject via online live session. Date and time are not decided yet but it will be planned within next 2 weeks after you enroll & pay for this course. Get in touch with our team if any clarification is required.

₹ 700

online

₹ 700

Why do you enroll

Key topics covered

Course details

Course tags

Why do you enroll

1. Parameters required for time calculation and their source --

2. Which parameters are from production department

3. Historical data / experience of doing similar components

4. Importance of calculating Machining time

5. Relevant formulae

6. Importance of tool geometry

7. Using Excel for simplifying your job

Show more

Key topics covered

- Why is time estimation required

- Which parts / products need it

- When is it done

- Whose responsibility is it

- What role production engineers play

- How accurate it must be

- What is the step by step process, formulae used

- Who provides the data

Show more

Course Details

Lathe machines are one of the most commonly used machines in manufacturing shops for turning, facing, boring, threading and allied operation. Cylindrical or profiled round components (symmetrical about an axis) is a major class of components required for all kinds of machineries / equipment. Lathe machines in variety of forms, of various sizes and capacities, configurations, including CNC control, are versatile machines. Capstan, turret, automats are the high productivity, settable versions of basic centre lathe, and are still in use in spite of take- over by CNC turning machines.

Estimating time that will be required for completing various operations, is essential for many reasons. Predicting delivery time, calculating cost of operation, production planning, are some of the reasons. Generally this is the responsibility of a person associated with production dept. viz production engineer, shift supervisor, shift engineer, and production manager level persons. In procurement dept / purchase dept, the vendor development engineer also need to know this. Ultimately, calculating the production cost of any product is the aim of collecting cost data at every stage of manufacturing. Machining operation cost is a major cost head.

Hence machining time estimation has assumed immense significance. Also it suggest factors which can reduce manufacturing cost. Value analysis techniques can be used for that.

Persons having the capability of doing this are always preferred by industry. Manufacturing cost of any product is very important and essential information for every manufacturer. Selling price of any product is generally 'Cost-based'.

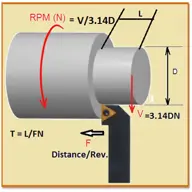

Lathe uses one of the basic cutting action i.e. "Rotating job - sliding tool', using single point cutting tool. Selecting proper feed, RPM, depth of cut etc need sufficient skill.

This short course is designed to impart essential skill required to calculate the of time each operation needs for finishing machined components. It explains the process involved in calculation, step by step and formulae used.

This knowledge is very essential for all who are associated with manufacturing activities in any capacity, Viz •

· Engineers responsible for production related activities

· Purchase / vendor development engineers

· Middle level managers responsible for day to day smooth operation of manufacturing activities as per production plan and within budgeted costs.

· Fresh engineers looking for job. This course will improve their employability.

· Owners / Directors of small and micro scale industries

· Final year students of engineering colleges.

· Persons planning for start up

This knowledge will further help in cost analysis and possibility of cost reduction improving marketability of their products. Suggestions for time reduction without hampering quality are always welcome by companies and are rewarded directly or indirectly like more responsible positions, higher remunerations.

It is advisable to do similar course on Milling machines operations since that machine is also widely used by industry. Other useful course will be on Tool Signature.

Show more

Course tags

FAQs on Estimation of machining time for Lathe machine operations

Having specific question ? Ask now

Trainer’s Feedback

1 course rating

1 ratings

SD

Shubham Deep

16 days ago

VIDEO LINK IS NOT ABLE TO OPEN

Certificate of Mastery

Receive well recognised certificate that you can showcase on

Featured courses

Hazard Identification and Risk Assessmen...

How to prevent corrosion in the oil and ...

Application and use of "Green Hydrogen"

Career in EPC projects for Freshers

Career in EPC Cost Estimation

Learn MATLAB Programming

More Technical Courses From Ashok Khopkar

LPG Basics - Specialised course for Begi...

Estimation of machining time for Lathe ...

Estimation of machining time for Milling...

What is LPG - Know More Closely

Understanding on Product costing - From ...

Understanding about Measuring units used...

Safety during transporting bulk LPG by r...

Spotlight on Safety features in LPG stor...

More Articles From Ashok Khopkar

"LPG for Beginners" Series of articles ...

“LPG for Beginners” Series of Articles ...

Machining Time Calculation

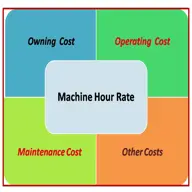

Machine Hour rate Calculation

“LPG FOR BEGINNERS” Series of Articles ...

“LPG for beginners" Series of article...

“LPG for Beginners” Serie...

"LPG for Beginners" Series of articles...

"LPG for Beginners" Series of articles...

More Communities From Ashok Khopkar

Similar Content Learn:

ASPEN PLUS

The Green Energy Transition: Sustainabil...

Solar Rooftop Power Plant Installation P...

E3D

Similar Content Mentor:

All About Interviews

Similar Content Seminar:

OIL & GAS AUTOMATION AND DIGITALISATION ...

7th International Oil & Gas Chemistry, C...

Similar Content Blogs:

Types of Piping Valves for Oil and Gas I...

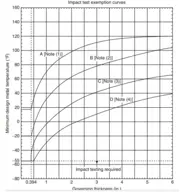

Technical Basis for Impact Test Exemptio...

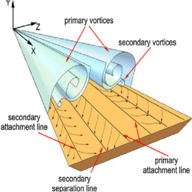

Aerodynamic physics of the Delta Wing

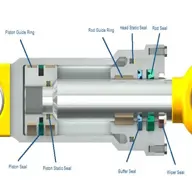

Seal of Hydraulic cylinder.

Similar Content Community:

Firefighting Design By Naga

Engineer's Corner

Cathodic protection

Corrosion

Similar Profile:

Vijay Sachdev

Consultant - Project & Pr...

Sabari Kuppuraj

Engineer

Mir Abbas

Senior Engineer

THE EXPERTS MEP SOLUTIONS

THE EXPERTS MEP SOLUTIONS

Anup Kumar Dey

Owner of https://whatispi...

Jyoti Swarup

--

Praveen Tiwari

--

Please wait