Corrosion Mechanism and Evaluation in Oil and Gas Industry

Language

English

314 Views

2 Enrollments

Share

Coming in January, 2025

-

-

This course format is where trainer will explain you the subject via online live session. Date and time are not decided yet but it will be planned within next 2 weeks after you enroll & pay for this course. Get in touch with our team if any clarification is required.

₹ 3499

online

₹ 3499

Why do you enroll

Key topics covered

Course details

Course tags

Why do you enroll

· Mastering corrosion mechanisms and control measures can open up new opportunities for roles in asset integrity management, facility maintenance, or corrosion engineering.

· Corrosion is one of the leading causes of costly repairs, downtime, and equipment replacement in the oil and gas industry. Professionals trained in corrosion control can help companies save money by implementing preventative maintenance strategies.

· Corrosion can lead to catastrophic failures, leaks, and environmental spills. Learning about corrosion prevention enhances operational safety and reduces the risks of accidents.

· The course will equip participants with essential skills to recognize, evaluate, and control corrosion using a combination of theoretical knowledge and practical tools, making them highly effective in their roles.

· Knowledge of industry standards and regulations will help participants ensure that their projects and facilities comply with global safety and environmental requirements.

· Effective corrosion control extends the lifespan of equipment, reducing the environmental impact and carbon footprint associated with frequent replacements or failures.

Summary

The Corrosion Mechanisms and Evaluation in Oil and Gas Industry course provides a comprehensive understanding of corrosion processes, evaluation techniques, and mitigation strategies essential to ensuring the longevity and safety of oil and gas infrastructure. Participants will gain valuable skills in identifying corrosion risks, applying corrosion control methods, and ensuring compliance with industry standards, thus contributing to operational safety, cost-efficiency, and sustainability in the oil and gas sector.

This course is ideal for engineers, technicians, maintenance personnel, and asset integrity managers seeking to expand their expertise in corrosion control and management. By completing this course, participants will be able to make informed decisions regarding materials selection, monitoring techniques, and preventive measures to effectively combat corrosion in oil and gas operations.

Show more

Key topics covered

Introduction to Corrosion in Oil and Gas

Basic principles of corrosion: electrochemical reactions, oxidation, and reduction

Overview of the oil and gas industry's corrosion challenges

Environmental factors affecting corrosion (e.g., high temperature, CO2, H2S)

Corrosion Mechanisms and Types

Uniform and localized corrosion (e.g., pitting and crevice corrosion)

Galvanic corrosion

Erosion-corrosion and cavitation

Stress Corrosion Cracking (SCC)

Corrosion under insulation (CUI)

Hydrogen embrittlement

Corrosion in Specific Environments

Corrosion in sour gas environments (H2S)

Corrosion in high-pressure, high-temperature (HPHT) systems

Corrosion in offshore and deepwater operations

Microbiologically influenced corrosion (MIC)

Materials Selection and Corrosion Resistance

Metal alloys used in oil and gas and their corrosion resistance properties (e.g., carbon steel, stainless steel, duplex)

Material selection for specific environments and operational conditions

Protective coatings and linings

Corrosion Monitoring and Inspection Techniques

Non-destructive testing (NDT) methods for corrosion detection (e.g., ultrasonic testing, radiography)

Use of corrosion probes, coupons, and sensors

Risk-based inspection (RBI) for pipeline and equipment monitoring

Corrosion Prevention and Control Methods

Cathodic protection: sacrificial anode and impressed current methods

Use of corrosion inhibitors in production systems

Application of protective coatings and linings

Chemical treatment programs for controlling corrosion in pipelines and wells

Corrosion inhibitors and nanotechnology, microbial monitoring and control

Autonomous Underwater Vehicles (AUVs)

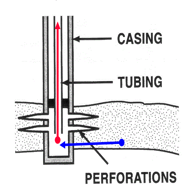

Corrosion agents in drilling and producing operations

Innovative technologies for corrosion detection and prevention in oil wells

Corrosion Management and Mitigation Strategies

Developing and implementing a corrosion management plan (CMP)

Integrating corrosion control into asset integrity management programs

Best practices for corrosion documentation and data management

Industry Standards and Regulatory Framework

NACE (National Association of Corrosion Engineers) standards

ISO corrosion-related standards

Environmental and safety regulations for corrosion control in oil and gas

Economic and Environmental Impact of Corrosion

Cost-benefit analysis of corrosion control programs

Reducing the environmental impact through corrosion prevention

Case studies of catastrophic failures due to corrosion and their consequences

Show more

Course Details

Corrosion is a significant issue in the oil and gas industry, leading to equipment failure, environmental hazards, and high maintenance costs. The Corrosion Mechanisms and Evaluation in the Oil and Gas Industry course is designed to equip engineers, maintenance personnel, and industry professionals with a thorough understanding of corrosion processes, preventive measures, and evaluation techniques. This course focuses on identifying various corrosion types, understanding their underlying mechanisms, and implementing strategies to mitigate their impact on oilfield equipment, pipelines, and production facilities.

Participants will learn about the root causes of corrosion in harsh environments such as deepwater drilling, high-pressure systems, and sour gas environments (H2S), as well as techniques to evaluate, monitor, and control corrosion using industry-standard methods.

Course Duration- 12 hr

The key objectives of the course are to:

Understand Corrosion Mechanisms: Explain the fundamental chemical and electrochemical processes that lead to corrosion in oil and gas operations.

Identify Corrosion Types: Teach participants to recognize and differentiate between various forms of corrosion (e.g., uniform, localized, galvanic, pitting, and stress corrosion cracking).

Evaluate Corrosion Risks: Enable participants to assess corrosion risks based on environmental and operational conditions such as temperature, pressure, water chemistry, and CO2/H2S content.

Implement Corrosion Prevention and Control: Provide strategies for corrosion control, including the use of coatings, inhibitors, cathodic protection, and material selection.

Corrosion Monitoring and Inspection: Learn to monitor and evaluate corrosion in pipelines and facilities using techniques like ultrasonic testing, corrosion coupons, and probes.

Understand Standards and Regulations: Familiarize participants with relevant standards (e.g., NACE, ISO) and safety regulations for managing corrosion in oil and gas operations.

Cost-Effectiveness and Safety: Focus on cost-effective corrosion control techniques that ensure safety, minimize environmental impact, and reduce the need for repairs or replacements.

Show more

Course tags

Industry domains :

Engineering Disciplines :

Difficulty Level :

FAQs on Corrosion Mechanism and Evaluation in Oil and Gas Industry

Having specific question ? Ask now

Certificate of Mastery

Receive well recognised certificate that you can showcase on

Featured courses

Hazard Identification and Risk Assessmen...

How to prevent corrosion in the oil and ...

Application and use of "Green Hydrogen"

Career in EPC projects for Freshers

Career in EPC Cost Estimation

Learn MATLAB Programming

More Technical Courses From Mohammad Al Jawhar

Reservoir Surviellance Planning

Basic Reservoir Management

WELL INTERVENTION TECHNIQUES

Oil Well Production Optimization

Corrosion Mechanism and Evaluation in Oi...

Similar Content Learn:

How to Make Career in "Instrumentation D...

Fundamentals of Quality, QMS & ISO-9001

Fundamentals of Quality, QMS & ISO-9001

Business Excellence through Quality, QMS...

Renewable Energy, Energy Storage Systems...

Oil Well Production Optimization

FRP /GRP Pipe Stress Analysis using Caes...

Similar Content Mentor:

All About Interviews

EPC Project Planning & Control - Procure...

Presentation Skills _ Part 2

How to motivate & encourage team bonding...

Time Management essentials for Engineers...

COMMUNICATE TO WIN - The most important ...

Similar Content Seminar:

The Petrochemical and Refining Congress:...

The Oil and Gas Decarbonisation Congress...

OIL & GAS AUTOMATION AND DIGITALISATION ...

7th International Oil & Gas Chemistry, C...

Similar Content Blogs:

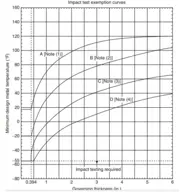

Technical Basis for Impact Test Exemptio...

A brief mathematical overview of the for...

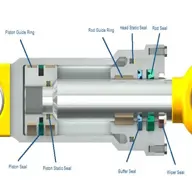

Seal of Hydraulic cylinder.

Reaching Net-Zero: The Power of Predicti...

AI Trends in the Oil and Gas Industry: U...

Welding Metallurgy

Production Chemicals Applications in Oil...

PRC Europe 2025: Italian Partners at the...

Similar Content Community:

Cathodic protection

Corrosion

Similar Profile:

Vijay Sachdev

Consultant - Project & Pr...

Sabari Kuppuraj

Engineer

Atul Kabre

Independent Consultant

Sawrabh Raj

Sr Instrumentation Design...

BGS Group

The organiser of closed-d...

HEXSPUR FOUNDATION

Mechanical Design Enginee...

Please wait