Risk Based Inspection

Language

English

90 Views

Share

Coming in April, 2025

-

-

This course format is where trainer will explain you the subject via online live session. Date and time are not decided yet but it will be planned within next 2 weeks after you enroll & pay for this course. Get in touch with our team if any clarification is required.

₹ 499

online

₹ 499

Why do you enroll

Key topics covered

Course details

Course tags

Why do you enroll

Mastering Risk-Based Inspection can significantly enhance your career in industries like Oil and Gas, Chemical Processing, and Power Generation, leading to roles like Inspection Manager, Reliability Engineer, or Maintenance Manager, with median salaries ranging from $90,000 to over $160,000. By developing expertise in identifying and mitigating potential failures, you'll become a highly sought-after professional. This skillset enables you to optimize inspection schedules, reduce costs, and ensure compliance with regulatory requirements. As a certified expert in Risk-Based Inspection, you'll be highly valued for your ability to analyze risk, develop inspection strategies, and drive asset reliability. Your expertise will also enable you to take on leadership roles, develop and implement risk-based inspection programs, and drive business growth. By mastering Risk-Based Inspection, you'll unlock new career opportunities, build a strong professional reputation, and achieve long-term success.

Show more

Key topics covered

Introduction to Risk-Based Inspection (RBI)

Understanding the concept of RBI and its importance in asset management

The relationship between risk management and inspection planning

Key benefits of RBI: optimizing inspection resources, reducing downtime, and enhancing safety

Fundamentals of Risk Assessment

Introduction to risk assessment: identifying hazards, evaluating likelihood, and determining consequences

Quantifying risk: the concept of risk as the combination of probability and impact

Using risk matrices to assess and prioritize risks

RBI Methodology

The RBI process: asset identification, risk assessment, inspection planning, and decision-making

Key components of RBI: failure modes, consequence analysis, and probability of failure

The role of risk ranking in determining inspection frequency and scope

Failure Modes and Effects Analysis (FMEA)

Introduction to FMEA as a tool for identifying potential failure modes of assets

Analyzing the effects of different failures on asset performance and safety

How to use FMEA to prioritize inspection efforts and resources

Criticality and Consequence Analysis

Assessing the criticality of assets and their impact on operations, safety, and the environment

Understanding the consequence of failure (e.g., financial, environmental, operational)

How criticality analysis influences inspection schedules and maintenance priorities

Probability of Failure and Inspection Frequency

Techniques for estimating the probability of asset failure based on historical data, inspections, and operational conditions

Determining inspection frequency based on risk levels and asset condition

Balancing the risk of failure with the cost and frequency of inspections

Inspection Planning and Resource Allocation

Developing an inspection plan based on RBI results

Allocating resources effectively to high-risk areas

Optimizing inspection intervals and methodologies (e.g., non-destructive testing, visual inspection, corrosion monitoring)

Data Collection and Analysis for RBI

The role of data collection in risk-based inspection: asset history, condition monitoring, operational data

Analyzing data to identify trends and predict future asset behavior

Integrating data sources (inspection reports, sensor data, maintenance records) into the RBI process

Integrating RBI with Asset Integrity Management

How RBI fits into a broader asset integrity management (AIM) program

Ensuring alignment between RBI findings and maintenance, reliability, and safety strategies

The role of RBI in decision-making and continuous improvement

Regulatory Standards and Compliance in RBI

Understanding relevant RBI standards, codes, and regulations (e.g., API 580, ASME, ISO 55000)

Ensuring RBI processes comply with industry standards and regulatory requirements

Auditing and documentation requirements for RBI programs

Show more

Course Details

This course is designed to provide participants with a thorough understanding of Risk-Based Inspection (RBI) principles and methodologies. RBI is a strategic approach that prioritizes inspection resources and activities based on the risk associated with asset failure. Participants will learn how to implement RBI to optimize maintenance efforts, reduce downtime, and ensure the safety and reliability of assets.

Show more

Course tags

Industry domains :

Engineering Disciplines :

FAQs on Risk Based Inspection

Having specific question ? Ask now

mg

mani giri

2 months ago

Very useful for me I'm inthe welding inspection filed so very useful full notes and tips I get through this and learning also lot

Certificate of Mastery

Receive well recognised certificate that you can showcase on

Featured courses

Hazard Identification and Risk Assessmen...

How to prevent corrosion in the oil and ...

Application and use of "Green Hydrogen"

Career in EPC projects for Freshers

Career in EPC Cost Estimation

Learn MATLAB Programming

More Technical Courses From Chaitanya Purohit

Mastering Project Management: Delivering...

Mastering Supply Chain Management: Optim...

Mastering Six Sigma: Driving Quality and...

Kaizen: The Art of Continuous Improvemen...

Welding Technology - Basics

Engineering Materials - Material Manufac...

Engineering Materials - Iron & Steel mak...

Engineering Materials - Material Classif...

Similar Content Learn:

Basic of CMS IntelliCAD and GD&T

Fundamentals of Quality, QMS & ISO-9001

Buffer Tank - Basic, Concept, Design, Ca...

Business Excellence through Quality, QMS...

Similar Content Mentor:

All About Interviews

Presentation Skills _ Part 2

Similar Content Seminar:

The Petrochemical and Refining Congress:...

OIL & GAS AUTOMATION AND DIGITALISATION ...

7th International Oil & Gas Chemistry, C...

Similar Content Blogs:

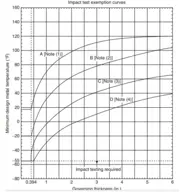

Technical Basis for Impact Test Exemptio...

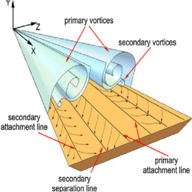

Aerodynamic physics of the Delta Wing

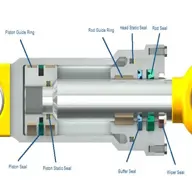

Seal of Hydraulic cylinder.

PRC Europe 2025: Italian Partners at the...

Similar Content Community:

Firefighting Design By Naga

Engineer's Corner

Cathodic protection

Corrosion

Cae engineers

Similar Profile:

Vijay Sachdev

Consultant - Project & Pr...

Debojyoti sen

MD & CEO, SAURYAJYOTI REN...

Sabari Kuppuraj

Engineer

Atul Kabre

Independent Consultant

Anup Kumar Dey

Owner of https://whatispi...

Jyoti Swarup

--

Praveen Tiwari

--

Please wait