Engineering Materials - Material Manufacturing Processes - Two Modules

Language

973 Views

2 Enrollments

Share

Coming in October, 2024

-

-

This course format is where trainer will explain you the subject via online live session. Date and time are not decided yet but it will be planned within next 2 weeks after you enroll & pay for this course. Get in touch with our team if any clarification is required.

₹ 699

online

₹ 699

Why do you enroll

Key topics covered

Course details

Course tags

Why do you enroll

Completing the two modules on Material Manufacturing Processes can significantly enhance your career prospects in the field of materials engineering. With in-depth knowledge of various manufacturing processes, you can transition into roles like Process Engineer, Materials Scientist, or Manufacturing Engineer, developing and optimizing materials production. Further advancements can lead to senior positions like Senior Research Engineer, Technical Director, or Plant Manager, overseeing the development and implementation of innovative material solutions. Additionally, this expertise can also open doors to careers in related fields like supply chain management, quality assurance, or research and development, offering a wide range of opportunities for professional growth and advancement in industries like aerospace, automotive, or energy.

Show more

Key topics covered

Industrial Manufacturing Processes Brief

Rolling,

Forging,

Hot Forming,

Cold Forming,

Casting,

Extrusion.

Show more

Course Details

The major classifications of engineering materials include metals, polymers, ceramics, and composites. The important characteristics of the materials within each of these classes are discussed in this course, and use of material properties are also explained. Engineering design materials to meet required properties to design an equipment & materials science plays an important role to understand the fundamental factors that influence the structure and properties of a material. such as thermodynamics, structural evolution, etc. This course is designed to provide in depth knowledge on various material manufacturing process.

You will learn various parameters after completing this course -

1. Different types of material manufacturing processes

2. importance and use of each process

3. Theoretical background behind each requirements which helps an engineer to understand the importance each making process.

4. An insight into the newly introduced methods, it's criteria and guidelines.

5. Bridging the gap between theoretical knowledge and practical application requirements.

6. University students who want to take up career in engineering or manufacturing department and wants to learn about the most widely used best practices and standard.

7. Experienced engineers who want to grow their career in engineering or production by understand the background of different types requirements

Show more

Course tags

Industry domains :

Engineering Disciplines :

FAQs on Engineering Materials - Material Manufacturing Processes - Two Modules

Having specific question ? Ask now

Trainer’s Feedback

5 course rating

1 ratings

mg

mani giri

19 days ago

Very useful for me I'm inthe welding inspection filed so very useful full notes and tips I get through this and learning also lot

Certificate of Mastery

Receive well recognised certificate that you can showcase on

Featured courses

Hazard Identification and Risk Assessmen...

How to prevent corrosion in the oil and ...

Application and use of "Green Hydrogen"

Career in EPC projects for Freshers

Career in EPC Cost Estimation

Learn MATLAB Programming

More Technical Courses From Chaitanya Purohit

Mastering Supply Chain Management: Optim...

Mastering Six Sigma: Driving Quality and...

Kaizen: The Art of Continuous Improvemen...

Welding Technology - Basics

Engineering Materials - Material Manufac...

Engineering Materials - Iron & Steel mak...

Engineering Materials - Material Classif...

Why NDT - Importance of Non Destructive ...

Similar Content Learn:

Introduction to Materials Science

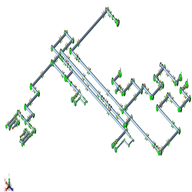

PV Elite Static Equipment Design

E3D Admin and SP3D Admin

Comprehensive Mechanical, Electrical, an...

Electrical Safety

Instrumentation and control in Real worl...

Process Design Engineering Full Course

Complete Course on Pressure Vessel Engin...

Similar Content Mentor:

All About Interviews

Presentation Skills _ Part 2

Similar Content Seminar:

7th International Oil & Gas Chemistry, C...

Similar Content Blogs:

The Importance of Steel in Construction

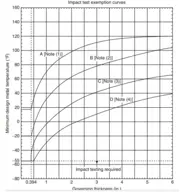

Technical Basis for Impact Test Exemptio...

A brief mathematical overview of the for...

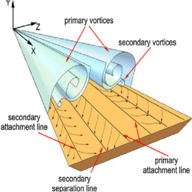

Aerodynamic physics of the Delta Wing

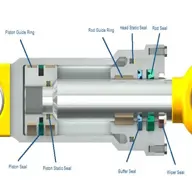

Seal of Hydraulic cylinder.

Similar Content Community:

Firefighting Design By Naga

Engineer's Corner

Cathodic protection

Corrosion

Cae engineers

Similar Profile:

Debojyoti sen

MD & CEO, SAURYAJYOTI REN...

Sabari Kuppuraj

Engineer

Atul Kabre

Independent Consultant

Dr Bhawani Singh Rathore

Renewable Energy Coach an...

Anup Kumar Dey

Owner of https://whatispi...

Jyoti Swarup

--

Praveen Tiwari

--