NDT ( RT ) Theory and Demonstration

Language

English

66 Views

Share

Coming in March, 2025

-

-

This course format is where trainer will explain you the subject via online live session. Date and time are not decided yet but it will be planned within next 2 weeks after you enroll & pay for this course. Get in touch with our team if any clarification is required.

₹ 499

online

₹ 499

Why do you enroll

Key topics covered

Course details

Course tags

Why do you enroll

Mastering Non-Destructive Testing (NDT) techniques, specifically Radiographic Testing (RT), can enhance your career in quality control, inspection, and testing, leading to roles like NDT Technician, Quality Inspector, or Testing Engineer, with median salaries ranging from $65,000 to over $110,000. You'll gain expertise to detect internal defects and anomalies using X-rays and gamma rays, ensuring product integrity and reliability in industries like aerospace, energy, and manufacturing, where safety and precision are paramount. This certification will also enable you to work on critical components, such as welds and castings, making you a valuable asset to employers.

Show more

Key topics covered

- Introduction to NDT and Radiographic Testing (RT)

- Overview of Non-Destructive Testing (NDT) methods and their role in quality control and safety

- Basic principles of Radiographic Testing (RT) and its advantages in detecting internal defects

- Common applications of RT across industries such as aerospace, oil & gas, manufacturing, and construction

- Fundamentals of Radiographic Testing (RT)

- Introduction to ionizing radiation: X-rays and gamma rays

- How RT works: The interaction of radiation with materials and its ability to reveal internal discontinuities

- The role of film or digital detectors in capturing radiographic images

- The concept of image contrast and density, and how these relate to material thickness and defect types

- Radiographic Testing Equipment

- Overview of RT equipment: X-ray machines, gamma-ray sources, film and digital radiography systems

- Safety features and operational components of RT equipment

- Selection of appropriate radiation sources: X-rays vs. gamma rays (e.g., cobalt-60, iridium-192)

- Calibration and setup of radiographic systems for accurate results

- Principles of Radiation and Image Formation

- How radiation passes through materials and the principles of absorption, attenuation, and scatter

- The formation of radiographic images and how defects cause changes in radiation transmission

- Understanding image quality: resolution, contrast, and exposure settings

- Factors influencing the final radiograph: exposure time, radiation energy, film type, and object thickness

- Techniques for Conducting Radiographic Inspections

- Step-by-step RT inspection procedures: setup, exposure, image development/processing

- Radiographic inspection techniques: single-wall, double-wall, and panoramic exposures

- Use of radiographic films, digital radiography (DR), and computed tomography (CT) in inspection

- Importance of proper film or detector positioning for high-quality results

- Calculating exposure times and radiation doses

- Interpreting Radiographic Images

- How to read radiographs and identify potential defects such as cracks, voids, porosity, and inclusions

- Differentiating between real indications and artifacts caused by geometry, shadows, or radiation scatter

- Understanding image density and contrast for defect characterization

- Types of defects typically detected in RT (e.g., linear cracks, incomplete welds, corrosion, or porosity)

- Evaluating defect size, location, and orientation from radiographs

- Safety Considerations in Radiographic Testing

- Radiation safety protocols for operators, technicians, and surrounding personnel

- Understanding radiation exposure limits, shielding, and distance rules

- Use of Personal Protective Equipment (PPE), including lead aprons, radiation badges, and barriers

- Safe handling of radioactive sources (gamma rays) and X-ray equipment

- Regulatory guidelines and safety standards (e.g., OSHA, NRC, IAEA)

- Radiographic Testing Standards and Codes

- Overview of industry standards: ASTM, ASME, ISO, and API related to RT

- Acceptance criteria for defects (size, location, and type) based on RT results

- RT reporting requirements and documentation practices for compliance with standards

- Importance of traceability and the proper handling of radiographs for future reference

- Practical Demonstration and Hands-On Experience

- Live demonstration of the RT process, including exposure setup, radiograph development, and interpretation of results

- Hands-on experience with radiographic equipment: Participants conduct inspections on test samples such as welds, pipes, and plates

- Evaluation of radiographs: Participants interpret results and identify defects in the radiographic images

- Troubleshooting common issues in RT: Overexposure, underexposure, and improper image interpretation

- Report Writing and Documentation in RT

- Best practices for documenting and reporting radiographic test results

- How to create clear and accurate inspection reports, including defect descriptions, images, and measurements

- Creating a radiographic inspection record for compliance with quality assurance and safety standards

- Certification and Competence in Radiographic Testing

- Overview of RT certification levels (Level I, II, III) and the qualifications required for each level

- Importance of maintaining certification through ongoing training and experience

- Role of RT technicians in ensuring the integrity of critical structures and safety of operations

Show more

Course Details

This course offers a comprehensive study of Radiographic Testing (RT), a widely used non-destructive testing (NDT) method that utilizes X-rays or gamma rays to inspect the internal structure of materials and components. Emphasizing both theoretical knowledge and practical skills, the course covers the principles, equipment, and techniques of RT, along with hands-on demonstrations to prepare students for effective and accurate inspections.

Show more

Course tags

Industry domains :

Engineering Disciplines :

FAQs on NDT ( RT ) Theory and Demonstration

Having specific question ? Ask now

mg

mani giri

2 months ago

Very useful for me I'm inthe welding inspection filed so very useful full notes and tips I get through this and learning also lot

Certificate of Mastery

Receive well recognised certificate that you can showcase on

Featured courses

Hazard Identification and Risk Assessmen...

How to prevent corrosion in the oil and ...

Application and use of "Green Hydrogen"

Career in EPC projects for Freshers

Career in EPC Cost Estimation

Learn MATLAB Programming

More Technical Courses From Chaitanya Purohit

Mastering Project Management: Delivering...

Mastering Supply Chain Management: Optim...

Mastering Six Sigma: Driving Quality and...

Kaizen: The Art of Continuous Improvemen...

Welding Technology - Basics

Engineering Materials - Material Manufac...

Engineering Materials - Iron & Steel mak...

Engineering Materials - Material Classif...

Similar Content Learn:

Basic of CMS IntelliCAD and GD&T

Fundamentals of Quality, QMS & ISO-9001

Buffer Tank - Basic, Concept, Design, Ca...

Business Excellence through Quality, QMS...

Similar Content Mentor:

All About Interviews

Presentation Skills _ Part 2

Similar Content Seminar:

7th International Oil & Gas Chemistry, C...

Similar Content Blogs:

Engineering Materials

The Importance of Steel in Construction

What is Piping Engineering?

Types of Piping Valves for Oil and Gas I...

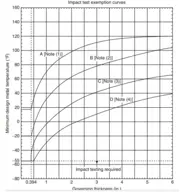

Technical Basis for Impact Test Exemptio...

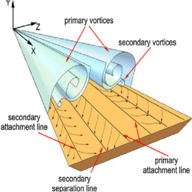

Aerodynamic physics of the Delta Wing

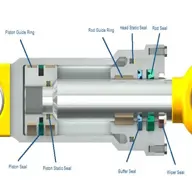

Seal of Hydraulic cylinder.

Similar Content Community:

Firefighting Design By Naga

Engineer's Corner

Cathodic protection

Corrosion

Cae engineers

Similar Profile:

Vijay Sachdev

Consultant - Project & Pr...

Debojyoti sen

MD & CEO, SAURYAJYOTI REN...

Sabari Kuppuraj

Engineer

Atul Kabre

Independent Consultant

Anup Kumar Dey

Owner of https://whatispi...

Jyoti Swarup

--

Praveen Tiwari

--

Please wait