Pipeline (HDPE Liners)

Language

English

97 Views

1 Enrollments

Share

Coming in February, 2025

-

-

This course format is where trainer will explain you the subject via online live session. Date and time are not decided yet but it will be planned within next 2 weeks after you enroll & pay for this course. Get in touch with our team if any clarification is required.

₹ 499

online

₹ 499

Why do you enroll

Key topics covered

Course details

Course tags

Why do you enroll

Mastering Pipeline (HDPE Liners) can significantly enhance your career in the oil and gas, water, and wastewater industries, leading to roles like Pipeline Engineer, Liner Installation Manager, or Pipeline Integrity Manager, with median salaries ranging from $90,000 to over $140,000. With this training, you'll gain expertise in the design, installation, and maintenance of high-density polyethylene (HDPE) liners for pipelines, ensuring corrosion resistance, leak prevention, and environmental protection. This knowledge will also equip you to develop and implement pipeline rehabilitation strategies, optimize liner selection and installation, and ensure compliance with industry standards and regulations. As a certified Pipeline (HDPE Liners) professional, you'll be highly sought after by companies seeking to extend pipeline lifespan, reduce maintenance costs, and ensure safe and reliable fluid transportation.

Show more

Key topics covered

Introduction to HDPE (High-Density Polyethylene) Liners

Overview of HDPE material properties: high-density polyethylene and its role in pipeline applications

Benefits of HDPE liners for pipelines: durability, chemical resistance, flexibility, and cost-effectiveness

Key applications of HDPE liners: wastewater, stormwater, industrial, agricultural, and mining pipelines

Comparison of HDPE with other pipeline materials (e.g., PVC, steel, and concrete) in terms of performance, cost, and longevity

HDPE Liner Material Properties and Specifications

Key properties of HDPE: high tensile strength, impact resistance, low friction coefficient, and UV stability

Chemical and corrosion resistance: resistance to acids, bases, solvents, and environmental degradation

Thermal properties: HDPE's ability to withstand temperature variations and thermal expansion/contraction

HDPE resin grades and standards (e.g., ASTM, ISO, and AWWA) and their impact on liner selection

Environmental considerations: recyclability, sustainability, and reduced ecological footprint

Manufacturing and Production of HDPE Liners

HDPE liner production process: extrusion and welding methods

Differences between smooth and textured HDPE liners

Thickness and dimensional considerations for HDPE liners in pipeline applications

Quality control in HDPE liner production: testing for material consistency, durability, and strength

HDPE liner certifications: ensuring compliance with international standards (e.g., NSF, AWWA, and ASTM)

Pipeline Design and HDPE Liner Selection

Factors influencing the selection of HDPE liners for specific pipeline projects: pressure, flow rate, and environment

Sizing HDPE liners: matching liner dimensions with pipeline diameter and length

Site-specific considerations: soil conditions, groundwater levels, and exposure to harsh chemicals

Selection of liner thickness based on internal pressure, external loads, and mechanical stress

Factors to consider in challenging environments: UV radiation, temperature extremes, and abrasion resistance

Installation of HDPE Liners in Pipeline Systems

Pre-installation considerations: site preparation, cleaning, and safety protocols

Liner installation methods: open-cut trench, trenchless methods (e.g., horizontal directional drilling), and slip-lining

HDPE fusion welding: butt fusion, electrofusion, and saddle fusion techniques

Proper alignment and handling of HDPE liners during installation

Best practices for installing HDPE liners in complex and challenging pipeline systems

Joining and Welding HDPE Liners

Overview of HDPE joining methods: fusion welding, mechanical joints, and flanged connections

Butt fusion welding: process, equipment, and quality control

Electrofusion welding: how it works, advantages, and applications

Socket fusion and saddle fusion techniques: when and where they are used

Quality assurance and testing of welded joints: visual inspection, hydrostatic testing, and ultrasonic testing

Common welding defects and troubleshooting techniques

HDPE Liner Performance in Pipeline Applications

Hydraulic performance: how HDPE liners improve flow efficiency through low friction and smooth surfaces

Longevity and durability: how HDPE resists wear, chemical attack, and biological growth

HDPE's resistance to cracking, stress corrosion, and environmental stress cracking (ESC)

Impact of ground movement, settlement, and external loads on HDPE-lined pipelines

Performance of HDPE liners under high-pressure conditions and extreme temperatures

Maintenance and Inspection of HDPE Lined Pipelines

Routine inspection practices for HDPE-lined pipelines: visual, ultrasonic, and remote sensing techniques

Methods for detecting leaks, cracks, or mechanical damage in HDPE liners

Non-destructive testing (NDT) for HDPE liners: methods and technologies (e.g., infrared thermography, acoustic testing)

Periodic maintenance and cleaning of HDPE pipelines: techniques to remove blockages, scale, and debris

Ensuring the integrity of welded joints and fusion points over time

Troubleshooting and Repair of HDPE Lined Pipelines

Common issues in HDPE-lined pipelines: leakage, damage, wear, and degradation

Techniques for repairing damaged HDPE liners: in-situ welding, patching, and replacement of damaged sections

Methods for patching leaks: heat welding, electrofusion, and mechanical methods

Addressing issues related to improper installation: alignment, fusion defects, and handling errors

The role of expert contractors and service providers in the repair and maintenance of HDPE systems

Environmental and Regulatory Considerations

Environmental benefits of using HDPE liners: sustainability, recyclability, and low environmental impact

Regulatory standards governing the use of HDPE in pipelines: water quality standards, environmental protection laws, and health guidelines

Compliance with local and international environmental regulations (e.g., LEED certification, NSF/ANSI 61 for potable water)

The role of HDPE liners in reducing pipeline leakage, preventing contamination, and safeguarding groundwater resources

Best practices for handling and disposing of HDPE liners after their service life

Show more

Course Details

This course offers an in-depth exploration of High-Density Polyethylene (HDPE) liners used in pipeline applications. Designed for engineers, construction professionals, and maintenance personnel, the course covers the properties, benefits, installation techniques, and maintenance practices associated with HDPE liners. Participants will gain practical knowledge on how to use HDPE liners to enhance pipeline performance, extend service life, and address various challenges in pipeline infrastructure.

Show more

Course tags

Industry domains :

Engineering Disciplines :

Mechanical , Metallurgy & Material Science , Piping & Layout

FAQs on Pipeline (HDPE Liners)

Having specific question ? Ask now

Trainer’s Feedback

5 course rating

1 ratings

mg

mani giri

2 months ago

Very useful for me I'm inthe welding inspection filed so very useful full notes and tips I get through this and learning also lot

Certificate of Mastery

Receive well recognised certificate that you can showcase on

Featured courses

Hazard Identification and Risk Assessmen...

How to prevent corrosion in the oil and ...

Application and use of "Green Hydrogen"

Career in EPC projects for Freshers

Career in EPC Cost Estimation

Learn MATLAB Programming

More Technical Courses From Chaitanya Purohit

Mastering Project Management: Delivering...

Mastering Supply Chain Management: Optim...

Mastering Six Sigma: Driving Quality and...

Kaizen: The Art of Continuous Improvemen...

Welding Technology - Basics

Engineering Materials - Material Manufac...

Engineering Materials - Iron & Steel mak...

Engineering Materials - Material Classif...

Similar Content Learn:

Fundamentals of Quality, QMS & ISO-9001

Buffer Tank - Basic, Concept, Design, Ca...

Business Excellence through Quality, QMS...

Similar Content Mentor:

All About Interviews

Presentation Skills _ Part 2

Similar Content Seminar:

7th International Oil & Gas Chemistry, C...

Similar Content Blogs:

PRC Europe 2025: Italian Partners at the...

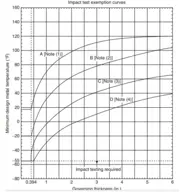

Technical Basis for Impact Test Exemptio...

A brief mathematical overview of the for...

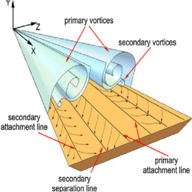

Aerodynamic physics of the Delta Wing

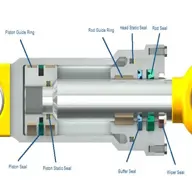

Seal of Hydraulic cylinder.

Similar Content Community:

Firefighting Design By Naga

Engineer's Corner

Cathodic protection

Corrosion

Cae engineers

Similar Profile:

Vijay Sachdev

Consultant - Project & Pr...

Debojyoti sen

MD & CEO, SAURYAJYOTI REN...

Sabari Kuppuraj

Engineer

Atul Kabre

Independent Consultant

Anup Kumar Dey

Owner of https://whatispi...

Jyoti Swarup

--

Praveen Tiwari

--

Please wait