PLC DCS Programming Overview

Language

English

229 Views

1 Enrollments

Share

Access anytime

78 Min

This course format through pre-recorded video. You can buy and watch it to learn at any time.

₹ 499

videos

₹ 499

Why do you enroll

Key topics covered

Course details

Course tags

Course content

Why do you enroll

This course particularly helps a fresher engineer and with some experience. Because it takes years to develop a mind which can program a PLC and DCS with a fail-safe logic.

Journey to this course add a new dimension in your skill set which sets you apart in talent pool and ofcourse increase productivity and efficiency of plant.

Key topics covered

These below topics will be covered in this course :

1. PLC DCS Programming Basic Rules

2. Difference between DCS PLC & Selection

3. How to Program Group Function Block

4. How to Program Motor Drive

5. How to Program Digital Input

6. How to Program Analog Input

7. How to Program PID controller

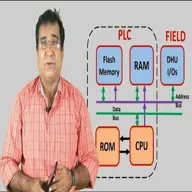

8. PLC Memory

9. Virtual PLC

Show more

Course Details

Though there are differenct language formats to write program for different make PLC and DCS system but the basic things are common to have in mind programming a PLC and DCS.

One must have an idea of how to program a Digital inputs / Analog inputs / Drive / PID controller and other things and what are its interface and interlock words to program plant or process condition This course lets you learn the basic requirement of programming any signal / drive / PID contrller in a PLC and DCS system.

The course have been supplied with practical experience added, which author has encountered and one must have in mind whenever programming a fool proof logic.

Show more

Course tags

Industry domains :

Engineering Disciplines :

Course content

1

PLC DCS Programming Basic Rules :

This video will teach you PLC programming and DCS pragramming basic rules. Not following PLC Programming, DCS programming rules may slow down PLC DCS controller while uploading and downloading program An Instrumentation Engineer must follow a standard system of PLC DCS programming or programming habits must be inculcated among instrumentation engineers so that control system can be efficient work, fault diagnosis become very fast and easy for control room operator to locate fault in alarm list itself. This video describes, with examples, some universal rules and precautions which an instrumentation engineer must take while programming

2

Difference between DCS PLC & Selection :

The video describes the difference between PLC Vs DCS and draws a line between the two for selection criteria while designing a new project. These days there is a very thin line difference between PLC and DCS. These two can replace each other as far as features are concerned. However, there are technical differences that still lie to make these two different. While discussing differences we will consider selection criteria when designing a new project.

3

How to Program Group Function Block :

This video describes "How a PLC DCS group function block is programmed in PLC and DCS"? There are instruments, equipment, or drives of common type or nature which are used in the process plant. These are monitored through centralized DCS or PLC Scada. Hence standard program function blocks are used rather than writing program repeatedly in the main program. These function blocks are scanned by common instruments or equipment repeatedly to execute logic. Here this video will cover and explains group function blocks and other function blocks will be covered consecutively in coming videos. if you have any queries or suggestion regarding this video you can post them in comment section

Show more

FAQs on PLC DCS Programming Overview

Having specific question ? Ask now

Certificate of Mastery

Receive well recognised certificate that you can showcase on

Featured courses

Hazard Identification and Risk Assessmen...

How to prevent corrosion in the oil and ...

Application and use of "Green Hydrogen"

Career in EPC projects for Freshers

Career in EPC Cost Estimation

Learn MATLAB Programming

More Technical Courses From Instrumentation Unlimited

PLC DCS Programming Overview

Variable Frequency Drive Fundamental and...

Similar Content Learn:

How to Make Career in "Instrumentation D...

Introduction to Heat Exchangers

How to Read Piping and Instrumentation D...

Powder X-ray Diffractometer: Theory and ...

Online Training Course on Instrumentatio...

Instrumentation and control in Real worl...

Similar Content Mentor:

All About Interviews

Presentation Skills _ Part 3

Presentation Skills _ Part 2

Similar Content Seminar:

OIL & GAS AUTOMATION AND DIGITALISATION ...

7th International Oil & Gas Chemistry, C...

Similar Content Blogs:

Internet of things (IoT) Applications in...

Next-Generation Communication Technologi...

Cybersecurity Trends Addressing Emerging...

Navigating Artificial Intelligence in He...

Seven Steps To Become A Discipline Trade...

What is Process Safety? Its Purpose, Ele...

Differences Between Static and Rotating ...

AUTOMA 2024: How Digital Technologies Ma...

Seal of Hydraulic cylinder.

PRC Europe 2025: Italian Partners at the...

Similar Content Community:

Engineer's Corner

Cathodic protection

Corrosion

Pressure Vessel & Piping

Similar Profile:

Debojyoti sen

MD & CEO, SAURYAJYOTI REN...

Atul Kabre

Independent Consultant

Sawrabh Raj

Sr Instrumentation Design...

Instrumentation Unlimited

An Instrumentation Engine...

Chirag Dave

Project Management

HEXSPUR FOUNDATION

Mechanical Design Enginee...

Yogesh Kulkarni

HVAC Audit Expert | Optim...

Please wait