GRE (Vessel / Piping/pipeline)

Language

English

80 Views

1 Enrollments

Share

Coming in February, 2025

-

-

This course format is where trainer will explain you the subject via online live session. Date and time are not decided yet but it will be planned within next 2 weeks after you enroll & pay for this course. Get in touch with our team if any clarification is required.

₹ 499

online

₹ 499

Why do you enroll

Key topics covered

Course details

Course tags

Why do you enroll

Mastering GRE (Glass Reinforced Epoxy) for Vessel, Piping, and Pipeline applications can significantly enhance your career in industries like oil and gas, chemical processing, and marine engineering, leading to roles like GRE Engineer, Composite Materials Specialist, or Pipeline Integrity Manager, with median salaries ranging from $100,000 to over $150,000. With this training, you'll gain expertise in designing, fabricating, and installing GRE systems for corrosion-resistant and durable applications, ensuring long-term performance and reliability. This knowledge will also equip you to develop and implement GRE-based solutions for complex engineering challenges, optimize system design and installation, and ensure compliance with industry standards and regulations. As a certified GRE professional, you'll be highly valued for your ability to deliver innovative, cost-effective, and sustainable solutions for demanding industrial applications.

Show more

Key topics covered

ntroduction to GRE (Glass Reinforced Epoxy) Materials

Overview of GRE: Definition, composition, and key characteristics of Glass Reinforced Epoxy

Advantages of GRE over traditional materials like steel, PVC, and concrete in vessels, piping, and pipelines

Properties of GRE: high strength-to-weight ratio, corrosion resistance, and excellent thermal stability

Applications of GRE in various industries: oil and gas, chemical processing, water treatment, and marine applications

Understanding the manufacturing process of GRE: fiber-reinforced composite materials and epoxy resin matrix

Material Properties of GRE for Pipeline and Vessel Applications

Mechanical Properties: tensile strength, compression strength, flexural strength, and impact resistance

Thermal Properties: thermal conductivity, operating temperature range, and coefficient of expansion

Chemical Resistance: resistance to acids, alkalis, solvents, salts, and other aggressive chemicals

Electrical Insulation: non-conductive nature of GRE for use in electrical and electronic systems

Corrosion Resistance: GRE's role in preventing corrosion and minimizing maintenance costs

Fatigue resistance and suitability for dynamic load applications in pipelines and vessels

Manufacturing and Fabrication of GRE Vessels, Piping, and Pipelines

Production processes for GRE components: filament winding, pultrusion, hand lay-up, and resin transfer molding (RTM)

Filament winding: process details, applications in pipeline and vessel manufacturing, and quality control

Pultrusion: continuous composite manufacturing process for GRE pipes and profiles

Resin systems and their impact on the properties of GRE: epoxy resins, curing agents, and additives

Fabrication of GRE fittings, flanges, joints, and valves: techniques for joining GRE components

Design Considerations for GRE Piping and Vessels

Load-bearing capacity and stress analysis for GRE piping and vessels

Wall thickness and pressure rating calculations based on fluid characteristics and operating conditions

Flexural and bending analysis for GRE pipes in dynamic environments (e.g., thermal cycling, seismic activity)

Design standards and codes for GRE piping systems: ASME, ASTM, ISO, and other international standards

Long-term performance prediction: understanding fatigue, creep, and stress rupture in GRE materials

Impact of installation and operational conditions (temperature, pressure, flow rate) on GRE systems

Installation of GRE Pipes and Vessels

Pre-installation preparation: handling, storage, and transportation of GRE pipes and components

Techniques for GRE pipe installation: trenchless technology, direct burial, and above-ground installation

Joints and connections: flange joints, threaded joints, bonded joints, and mechanical couplings

Installation of GRE vessels: mounting, support, and anchorage considerations

Handling of GRE during installation: special tools, lifting techniques, and protection from damage during transport and installation

Jointing and Welding Techniques for GRE

Types of joints for GRE piping systems: butt fusion, socket fusion, and adhesive bonding

Methods for joining GRE pipes: electrofusion welding, mechanical couplings, and flanged connections

Installation and inspection of GRE couplings and fittings

Quality assurance and testing of joints: visual inspection, hydrostatic testing, and ultrasonic testing

Maintenance and repair of GRE joints: methods for repairing leaks and cracked joints without full system replacement

Corrosion Resistance and Maintenance of GRE Systems

Corrosion resistance of GRE piping and vessels in harsh environments (e.g., chemicals, seawater, soil exposure)

Common forms of degradation: UV degradation, surface cracking, and chemical attack

Protective coatings for GRE: UV-resistant coatings and anti-abrasion coatings for external surfaces

Preventive maintenance strategies: monitoring and inspecting GRE systems for potential damage, wear, or degradation

Techniques for repairing and restoring damaged GRE components: patching, reinforcement, and re-lining

Testing and Quality Control for GRE Pipelines and Vessels

Types of testing for GRE pipelines: hydrostatic testing, pneumatic testing, and pressure testing

Non-destructive testing (NDT) techniques: ultrasonic testing, radiography, and visual inspection

Destructive testing for GRE: tensile, compression, and impact testing of GRE materials and joints

Quality control procedures during manufacturing, installation, and operation of GRE systems

Ensuring compliance with industry standards: ASTM, ISO, and local/regional regulations

Fire Resistance and Safety Considerations

Fire safety of GRE systems: materials' behavior under extreme temperatures and fire conditions

GRE’s fire-resistant properties: fire retardant additives and coatings for GRE pipes and vessels

Safety protocols for working with GRE materials: handling, installation, and disposal of GRE components

Fire protection strategies for GRE pipelines in hazardous environments (e.g., oil and gas, chemical processing)

Regulatory requirements for fire safety in GRE applications and fire-resistant testing standards

Cost Considerations and Life Cycle Cost Analysis (LCCA)

Initial costs of GRE vs. traditional materials (e.g., steel, PVC, and concrete)

Long-term operational costs: maintenance, corrosion protection, and energy efficiency

Total cost of ownership: factoring in installation, lifespan, and repair/replacement costs

Lifecycle cost analysis for GRE piping and vessels in industrial, municipal, and commercial applications

Cost-benefit analysis of using GRE for specific applications (e.g., chemical transport, water systems)

Show more

Course Details

This comprehensive course provides an in-depth exploration of Glass Reinforced Epoxy (GRE) technology and its applications in vessel, piping, and pipeline systems. Designed for engineers, designers, and industry professionals, the course covers the fundamental principles, design considerations, installation practices, and maintenance strategies associated with GRE systems.

Course tags

Industry domains :

Engineering Disciplines :

Mechanical , Metallurgy & Material Science , Piping & Layout

FAQs on GRE (Vessel / Piping/pipeline)

Having specific question ? Ask now

Trainer’s Feedback

5 course rating

1 ratings

mg

mani giri

2 months ago

Very useful for me I'm inthe welding inspection filed so very useful full notes and tips I get through this and learning also lot

Certificate of Mastery

Receive well recognised certificate that you can showcase on

Featured courses

Hazard Identification and Risk Assessmen...

How to prevent corrosion in the oil and ...

Application and use of "Green Hydrogen"

Career in EPC projects for Freshers

Career in EPC Cost Estimation

Learn MATLAB Programming

More Technical Courses From Chaitanya Purohit

Mastering Project Management: Delivering...

Mastering Supply Chain Management: Optim...

Mastering Six Sigma: Driving Quality and...

Kaizen: The Art of Continuous Improvemen...

Welding Technology - Basics

Engineering Materials - Material Manufac...

Engineering Materials - Iron & Steel mak...

Engineering Materials - Material Classif...

Similar Content Learn:

Fundamentals of Quality, QMS & ISO-9001

Buffer Tank - Basic, Concept, Design, Ca...

Business Excellence through Quality, QMS...

Similar Content Mentor:

All About Interviews

Presentation Skills _ Part 2

Similar Content Seminar:

7th International Oil & Gas Chemistry, C...

Similar Content Blogs:

PRC Europe 2025: Italian Partners at the...

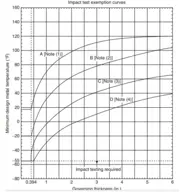

Technical Basis for Impact Test Exemptio...

A brief mathematical overview of the for...

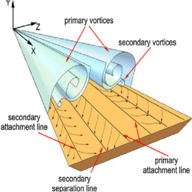

Aerodynamic physics of the Delta Wing

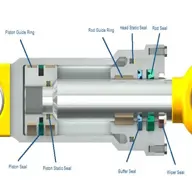

Seal of Hydraulic cylinder.

Similar Content Community:

Firefighting Design By Naga

Engineer's Corner

Cathodic protection

Corrosion

Cae engineers

Similar Profile:

Vijay Sachdev

Consultant - Project & Pr...

Debojyoti sen

MD & CEO, SAURYAJYOTI REN...

Sabari Kuppuraj

Engineer

Atul Kabre

Independent Consultant

Anup Kumar Dey

Owner of https://whatispi...

Jyoti Swarup

--

Praveen Tiwari

--

Please wait