Mechanical Rotary Equipment & Packages Masterclass: From Basics to Expertise

Language

English

16 Views

Share

March 15, 2025

2:30 PM (Local)

45 Hrs

This course format is where trainer will explain you the subject via online live session. This course will run as per specific date and time.

₹ 39999

online

₹ 39999

Why do you enroll

Key topics covered

Course details

Course tags

Why do you enroll

This course is designed to transform your understanding of mechanical rotary equipment and packaged systems, equipping you with the knowledge and skills to excel in engineering and industrial operations. Whether you're an aspiring engineer or an industry professional, our masterclass provides:

Key Value Propositions:

Comprehensive Knowledge:

Gain in-depth insights into rotary equipment like pumps, compressors, turbines, and packaged systems with real-world applications.Practical Skills:

Master design principles, operation protocols, maintenance techniques, and troubleshooting strategies for optimal system performance.Industry-Relevant Expertise:

Stay ahead in your field with a curriculum aligned to modern industrial standards, codes, and best practices.Interactive Learning:

Engage with expert-led sessions, hands-on exercises, and real-world case studies for an immersive educational experience.Career Advancement:

Build a strong technical foundation that positions you for growth, from technical roles to leadership opportunities in engineering.

Takeaway:

By the end of this masterclass, participants will be equipped with the confidence and expertise to handle rotary equipment and packaged systems efficiently, adding value to their organizations and boosting their careers.

Show more

Key topics covered

Introduction to Mechanical Rotary Equipment:

Overview of pumps, compressors, turbines, and their roles in industrial applications.

Types and classifications of rotary equipment.

Design Principles:

Selection criteria for rotary equipment.

Key parameters influencing design and performance.

Material selection and compatibility.

Operation and Performance:

Fundamentals of rotary equipment operation.

Understanding performance curves and operating limits.

Efficiency optimization techniques.

Maintenance and Reliability:

Preventive and predictive maintenance practices.

Troubleshooting common issues in rotary equipment.

Vibration analysis and condition monitoring.

Packaged Systems Overview:

Introduction to mechanical packaged systems.

Integration of rotary equipment into packaged units.

System-level design and operational considerations.

Codes, Standards, and Compliance:

Industry standards (API, ASME, ISO) for rotary equipment.

Safety and compliance requirements.

Advanced Topics:

Emerging technologies in rotary equipment.

Innovations in energy efficiency and sustainability.

Real-World Applications and Case Studies:

Case studies from oil & gas, petrochemical, power, and process industries.

Practical problem-solving exercises.

Career and Industry Insights:

Best practices for engineers working with rotary equipment.

Industry trends and future opportunities.

Show more

Course Details

To provide a comprehensive understanding of mechanical rotary equipment and packaged systems, enabling participants to design, operate, and maintain them effectively.

Covers fundamentals, design principles, operation, maintenance, and troubleshooting of rotary equipment like pumps, compressors, turbines, and packaged systems used in industrial applications.

Course tags

Industry domains :

Engineering Disciplines :

Difficulty Level :

Roles :

FAQs on Mechanical Rotary Equipment & Packages Masterclass: From Basics to Expertise

Having specific question ? Ask now

MA

Mohd Afzan Hamizan Abdul Rahman

4 months ago

good

PK

PRATHAMESH KUMBHAR

5 months ago

its helpful

AN

Aung Naung

6 months ago

Great . Well presentation with brief explanation on PMS.

AJ

Anuj Jagadale

6 months ago

Love the lecture! Presentation were onto to the point. Gained maximum knowledge in little time.

PR

Pradeep Raju Jampana

6 months ago

This was a great class and good explanation.

AA

Atul Adke

6 months ago

It was great session. Thank you for efforts and supports.

Xj

Xena jin

6 months ago

Honestly, the live class was pretty good. Very informative and free on top of that

MH

Mohammad Hashim Raza

6 months ago

It was highly informative and presenter is amazingly expert in the subject.

VH

Varci Horácio

6 months ago

The session was very informative, however it would be better to include all images in the presentation to avoid switching screens to google

MG

Mahesh Gholap

6 months ago

It was nice presentation....

AS

Azhar Shaikh

6 months ago

It was good

SG

Shubham Gage

6 months ago

Very beautiful course

FA

Fahrell Adlinizar

6 months ago

Good explanation

DS

Darshan Shingane

6 months ago

Good

JD

Jody Donysius

6 months ago

Good presentation. Thank you so much

MR

Mohammed Rizvi Uvais

6 months ago

It is outstanding brief explanation of PMS and well prepared and presented.

TN

THET NAING TUN

6 months ago

complete intro and very informative. Recorded video is showing to buy 89 INR. For attendees, it should be free.

MJ

Mohamed Javeed

6 months ago

The presentation was informative and we look for more in-depth details of piping materials and its workflow with project examples will be very easy to access for the junior level engineer like us .

P

Prasanna Ramasamy

6 months ago

More details and rules of thumb to remember the material specifications for different fluids and temperature based classification would be helpful.

SN

Sulist Nurwahyudi

6 months ago

So far..its a Good explanation

AR

Ali Raza

6 months ago

The course was intriductory level and I was expecting some good information as a stress engineer

Certificate of Mastery

Receive well recognised certificate that you can showcase on

Featured courses

Hazard Identification and Risk Assessmen...

How to prevent corrosion in the oil and ...

Application and use of "Green Hydrogen"

Career in EPC projects for Freshers

Career in EPC Cost Estimation

Learn MATLAB Programming

More Technical Courses From Team Piping Engineering

Essential Piping Engineering: Design, Ma...

Piping Material Specification and relate...

SP3D ADMINISTRATION

E3D

AutoCAD

SP3D

Piping Engineering

Piping Material Specification and relate...

Similar Content Learn:

Solidworks Advanced

CMS IntelliCAD Advanced 2D

CMS IntelliCAD Intermediate 2D

CMS IntelliCAD Basic 2D

Mechanical Rotary Equipment & Packages M...

Installation process of Solar System in ...

Hydraulic System Basic & Machine Design.

Similar Content Mentor:

The Science on Ekadashi (11th day) fasti...

All About Interviews

How to motivate & encourage team bonding...

Time Management essentials for Engineers...

COMMUNICATE TO WIN - The most important ...

Similar Content Seminar:

The Petrochemical and Refining Congress:...

The Oil and Gas Decarbonisation Congress...

OIL & GAS AUTOMATION AND DIGITALISATION ...

7th International Oil & Gas Chemistry, C...

Similar Content Blogs:

A brief mathematical overview of the for...

PRC Europe 2025: Italian Partners at the...

Reaching Net-Zero: The Power of Predicti...

What is Piping Engineering?

Types of Piping Valves for Oil and Gas I...

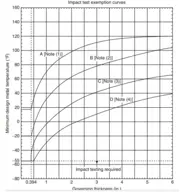

Technical Basis for Impact Test Exemptio...

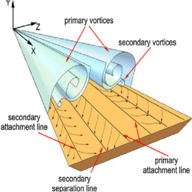

Aerodynamic physics of the Delta Wing

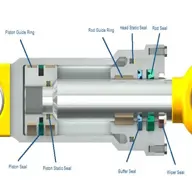

Seal of Hydraulic cylinder.

Similar Content Community:

Firefighting Design By Naga

Engineer's Corner

Corrosion

Pressure Vessel & Piping

Cae engineers

Similar Profile:

Hira Lal

Engineer

Vijay Sachdev

Consultant - Project & Pr...

Sabari Kuppuraj

Engineer

Atul Kabre

Independent Consultant

Sawrabh Raj

Sr Instrumentation Design...

Please wait