Casting

Language

English

169 Views

2 Enrollments

Share

Access anytime

450 Min

This course format through pre-recorded video. You can buy and watch it to learn at any time.

FREE

videos

FREE

Why do you enroll

Key topics covered

Course details

Course tags

Course content

Why do you enroll

Unlock the secrets of casting and transform your manufacturing skills! Our comprehensive casting course covers the fundamentals of sand casting, investment casting, die casting, and more. Learn from industry experts and master the techniques to produce high-quality castings with precision and accuracy. Ideal for foundry professionals, engineers, and manufacturers, this course will enhance your knowledge, improve productivity, and boost your career prospects.

Enroll now and:

- Master casting processes and techniques

- Improve product quality and reduce defects

- Increase efficiency and productivity

- Stay competitive in the industry

Show more

Key topics covered

- Introduction of Casting

- Casting Terminology

- Pattern Allowances

- Sand Moulding

- Gating system

- Shell Mould Casting

Course Details

Casting is a manufacturing process that involves pouring molten metal into a mold to create a desired shape or design. This ancient technique has been refined over centuries and is widely used in various industries, including aerospace, automotive, medical, and industrial applications. The casting process begins with creating a pattern or replica of the desired shape, followed by preparing the mold cavity. The molten metal is then poured into the mold, allowed to solidify, and removed once cooled. The resulting product, called a casting, can be made from a range of materials, including ferrous and non-ferrous metals, superalloys, and composites.

The versatility of casting lies in its ability to produce complex geometries and intricate designs, making it an ideal method for creating components such as engine blocks, cylinder heads, gearboxes, and turbine blades. Additionally, casting enables high-volume production through techniques like die casting and continuous casting. However, casting also presents challenges, including material limitations, defects, dimensional accuracy, and surface finish. To overcome these issues, foundries employ various techniques, such as gravity casting, pressure casting, vacuum casting, and squeeze casting.

The benefits of casting are numerous, including cost-effectiveness, reduced machining and assembly costs, and the ability to produce complex shapes. Casting also allows for material versatility, enabling the use of various metals and alloys. With advancements in technology and simulation software, casting has become increasingly precise, enabling the production of high-quality components with improved mechanical properties. As a result, casting remains a vital manufacturing process, driving innovation and productivity across diverse industries.

Show more

Course tags

Industry domains :

Engineering Disciplines :

Course content

1

Steps of Casting Processes :

2

Casting: Terminology :

3

The Pattern Allowances I :

Show more

FAQs on Casting

Having specific question ? Ask now

Trainer’s Feedback

4 course rating

39 ratings

AF

A Fabio Riyan

2 months ago

Very useful to budding engineers

VN

VIKAS_D_ NAYAK

3 months ago

usefull

UM

URK20AE1047 MOSES

3 months ago

very useful for beginners

PS

Prathamesh Shevale

3 months ago

Excellent course.

MM

Mostafa Mohamed Elsayed

3 months ago

Good

SS

SANJAY S 22CHR058

4 months ago

Good

FK

Farhan Khan

4 months ago

Good course

MS

Marthin Siagian

4 months ago

Good Course

AA

Ayan Adhikary

4 months ago

Great 👍

AH

ABDUL HASIB HASAN ZAYED

5 months ago

Very good.

TE

Team EveryEng

5 months ago

Good

PE

Process Engineering World

5 months ago

Good

PP

Prasenjit Pandit

5 months ago

Well narrated !!

TH

Tc.Mohd Hairul Jamaludin

6 months ago

Good

TH

Tc.Mohd Hairul Jamaludin

6 months ago

Good knowledge

AJ

Anuj Jagadale

6 months ago

well prepared content.

AJ

Anuj Jagadale

6 months ago

Highly appreciable content made.

TE

Team EveryEng

6 months ago

Good course

MR

Mohammed Rizvi Uvais

7 months ago

Well prepared presentation

MA

Mario Alberto Aguilar Herrera

7 months ago

Simple but excellent explaining

SC

SARTHAK CHAVAN

10 months ago

The lecture was quite good and interesting

HN

Harishankar Nagapuri

10 months ago

Excellent

SN

Shripad Nilakhe

10 months ago

Nice

NG

Nishanth G

10 months ago

Good Seminar

D2

DAVE 2D

10 months ago

Good session and explain as i expected

SK

Srinivasulu Killa

10 months ago

Good

bm

bhavin mehta

a year ago

Excellent course.

SA

Syed Aamir

a year ago

Good

SG

Sampath G

4 months ago

nicely explained

MY

MUHAMMAD YOUSUF KHAN

6 months ago

good good

PK

Prasanna Koduru

7 months ago

Good

SG

Sampath G

4 months ago

Should have discussed ddetails like 1.why density based solver. 2.why pressure boundary conditions. 3.How pressure values affect the working of nozzle etc

MF

Mustahid Fahim

3 months ago

Lectures are good but it's already available in the YouTube nptel lectures why should I watch here

KM

Khushal Mahajan

3 months ago

Why uploading NPTEL videos on your site ?

NA

Noor Alam

6 months ago

Good

YD

Yogesh Desai

a month ago

Useless

JK

Jahanzeb Khan

5 months ago

where are the other video

rk

recheal komugisa

7 months ago

Request for the video

TK

TANMAY KULAYE

10 months ago

Only one video is uploaded, rest of the videos are not there. 👎👎👎 Please upload other videos of Green Hydrogen.

Certificate of Mastery

Receive well recognised certificate that you can showcase on

Featured courses

Hazard Identification and Risk Assessmen...

How to prevent corrosion in the oil and ...

Application and use of "Green Hydrogen"

Career in EPC projects for Freshers

Career in EPC Cost Estimation

Learn MATLAB Programming

More Technical Courses From Team EveryEng

Pressure Vessel Essentials: Need of code...

How to prevent corrosion in the oil and ...

Application and use of "Green Hydrogen"

Gas Turbines with special emphasis on hy...

Career in EPC projects for Freshers

Career in EPC Cost Estimation

Bolt Torque Calculations using Dennis Mo...

Introduction to SAP and its role in the ...

More Articles From Team EveryEng

Davisson and Germer Experiment

Compton Scattering Effect

Coherent Source

Black Body Radiation

The engineering services is changing and...

What is first, YOU or YOUR COUNTRY?

Visionary Leaders make the nation great

Engineers need business acumen to be suc...

Collaboration is the first step of intel...

More Communities From Team EveryEng

Similar Content Learn:

Different element types commonly used in...

CMS IntelliCAD Advanced 2D

CMS IntelliCAD Intermediate 2D

CMS IntelliCAD Basic 2D

Hydraulic System Basic & Machine Design.

Similar Content Mentor:

All About Interviews

Similar Content Seminar:

7th International Oil & Gas Chemistry, C...

Similar Content Blogs:

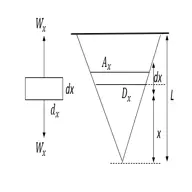

Axial Deflection of Bars due to the self...

Mechanical Engineering - GATE Exam Sylla...

Welding Metallurgy

Engineering Materials

The Importance of Steel in Construction

What is Piping Engineering?

Types of Piping Valves for Oil and Gas I...

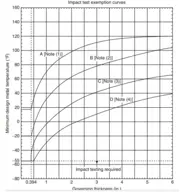

Technical Basis for Impact Test Exemptio...

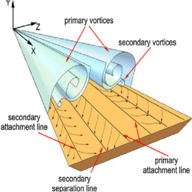

Aerodynamic physics of the Delta Wing

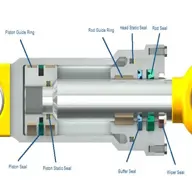

Seal of Hydraulic cylinder.

Similar Content Community:

Firefighting Design By Naga

Engineer's Corner

Corrosion

Pressure Vessel & Piping

Cae engineers

Similar Profile:

Hira Lal

Engineer

Vijay Sachdev

Consultant - Project & Pr...

Debojyoti sen

MD & CEO, SAURYAJYOTI REN...

Mir Abbas

Senior Engineer

HEXSPUR FOUNDATION

Mechanical Design Enginee...

Please wait