Industry 4.0 - Automation & Applications

Language

English

138 Views

Share

Access anytime

150 Min

This course format through pre-recorded video. You can buy and watch it to learn at any time.

₹ 349

₹ 349

Why do you enroll

Key topics covered

Course details

Course tags

Course content

Why do you enroll

Embrace the future of manufacturing with our "Industry 4.0 - Automation & Applications" course! This cutting-edge program dives into the transformative technologies shaping the fourth industrial revolution, including IoT, AI, robotics, and data analytics. You’ll learn how to implement automation solutions and optimize processes for increased efficiency and productivity in modern industries.

Join us and position yourself at the forefront of Industry 4.0—enroll today and start your journey toward innovation!

Show more

Key topics covered

- Classification of automation & types of control systems, Ethical dilemma of automation.

- Robotics - Robot definition, classification, components & configuration, Laws of robotics, degree of freedom in robotics.

- NC & CNC machines components, types, higher-axes machining, G CODE & M CODE, programming format, applications.

- 3D Printing Procedures, processes, materials & applications.

Show more

Course Details

"The next industrial revolution is bringing about untold change in every industry creating massive advantages and challenges to implement."

Industry 4.0 is the digital transformation of manufacturing/production and related industries and value creation processes. Industry 4.0 is used interchangeably with the fourth industrial revolution and represents a new stage in the organization and control of the industrial value chain. The implementation of industry 4.0 is giving birth to smart manufacturing practices and smart factories. Increasing productivity and revenue exponentially. In short we can say - The Fourth Industrial Revolution (or Industry 4.0) is the ongoing automation of traditional manufacturing and industrial practices, using modern smart technology (Like Robotics,CNC,3D printing etc.)

Smart Manufacturing and Smart Factories bring with them optimizations and a growing ability to self-optimize production leading to nearly zero downtime. Optimization will play a major role in keeping high end equipment maintained efficiently by having the right resources in the right place at the right time. Being able to utilize your production capacity constantly and consistently is better than a major down time or changeover. While IIOT (Industrial Internet Of Things) and M2M (Machine to Machine communication) are in the lead, Automation and related applications, Is playing a vital role in shaping the ecosystem of Industry 4.0.

This course is designed to cover the automation & application portion of Industry 4.0. This is very beneficial for students from mechanical, manufacturing & Industrial engineering stream. Moreover, Those professionals who are already a part of any manufacturing industry, will get the additional knowledge of various development in the field of technology which can revolutionize their existing practices. So this course is not only for aspiring engineers but also for working professionals. Some of the areas of automation & applications in industry 4.0 covered in the course is elaborated below :

Automation - Classification, Control system & challenges

Robotics - Definition, Laws of robotics, Components of a robot, Robot classification, DOF - Degree Of Freedom, Robot configurations and some exceptional robots available in industry.

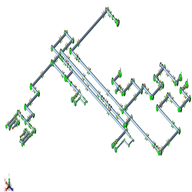

Numerical Control - NC & CNC machines, Components of CNCs, Types of CNCs, Importance of higher axes machining, Programming format, CODING exercise (G-Code), Applications.

3D Printing - General Explanation, Procedure, Types of 3D printing processes, Materials & applications.

Show more

Course tags

Industry domains :

Engineering Disciplines :

Course content

1

Industry 4.0 - the fourth industrial revolution :

2

Classification of automation :

In industry point of view – “Automation is the creation and application of technology to monitor and control the production & delivery of product & services.” There are three types of automation – Permanent, Programmable & Flexible.

3

Types of control system :

A control system manages, commands, directs, or regulates the behaviour of other devices or systems using control loops. It can range from a single home heating controller using a thermostat, controlling a domestic boiler to large industrial control systems which are used for controlling processes or machines. There are three types of control systems – Pneumatic, Hydraulic & Electrical.

Show more

FAQs on Industry 4.0 - Automation & Applications

Having specific question ? Ask now

Certificate of Mastery

Receive well recognised certificate that you can showcase on

Featured courses

Hazard Identification and Risk Assessmen...

How to prevent corrosion in the oil and ...

Application and use of "Green Hydrogen"

Career in EPC projects for Freshers

Career in EPC Cost Estimation

Learn MATLAB Programming

More Technical Courses From J Aatish Rao

Engineering Mathematics - Numerical Anal...

Mechanics 101: A Beginner's Guide to Mec...

Heat And Mass Transfer - HMT

100+ MECHANICAL Engineering INTERVIEW Qu...

Internal Combustion Engines

Industrial Engineering - Operations Rese...

Workshop Technology OR Machine Shop Theo...

Introduction to CNC Programming

Similar Content Learn:

Basic of CMS IntelliCAD and GD&T

Fundamentals of Quality, QMS & ISO-9001

Buffer Tank - Basic, Concept, Design, Ca...

Business Excellence through Quality, QMS...

Renewable Energy, Energy Storage Systems...

Similar Content Mentor:

All About Interviews

Presentation Skills _ Part 2

How to motivate & encourage team bonding...

Time Management essentials for Engineers...

COMMUNICATE TO WIN - The most important ...

Similar Content Seminar:

The Petrochemical and Refining Congress:...

The Oil and Gas Decarbonisation Congress...

OIL & GAS AUTOMATION AND DIGITALISATION ...

7th International Oil & Gas Chemistry, C...

Similar Content Blogs:

A brief mathematical overview of the for...

PRC Europe 2025: Italian Partners at the...

Reaching Net-Zero: The Power of Predicti...

What is Piping Engineering?

Types of Piping Valves for Oil and Gas I...

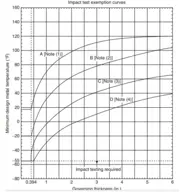

Technical Basis for Impact Test Exemptio...

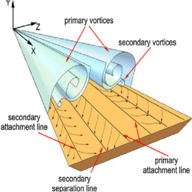

Aerodynamic physics of the Delta Wing

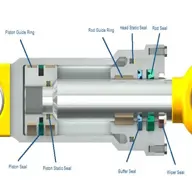

Seal of Hydraulic cylinder.

Similar Content Community:

Firefighting Design By Naga

Engineer's Corner

Cathodic protection

Corrosion

Similar Profile:

Vijay Sachdev

Consultant - Project & Pr...

Debojyoti sen

MD & CEO, SAURYAJYOTI REN...

Sabari Kuppuraj

Engineer

BGS Group

The organiser of closed-d...

Mir Abbas

Senior Engineer

THE EXPERTS MEP SOLUTIONS

THE EXPERTS MEP SOLUTIONS

J Aatish Rao

Mechanical Engineering Pr...

Chirag Dave

Project Management

Please wait