Mastering Pipe Stress Analysis using Caesar II Software (Basics to Advanced) with Certification

Anup Kumar Dey

Owner of https://whatispiping.com/

$ 500

31 already enrolled!

Advanced course for professionals

Anytime Learning

Learn from Industry Expert

Career Option Guideline

Mastering Pipe Stress Analysis using Caesar II Software (Basics to Advanced) with Certification

Trainers feedback

5

(1 reviews)

Anup Kumar Dey

Owner of https://whatispiping.com/

Course type

Watch to learn anytime

Course duration

2161 Min

Course start date & time

Access anytime

Language

English

This course format through pre-recorded video. You can buy and watch it to learn at any time.

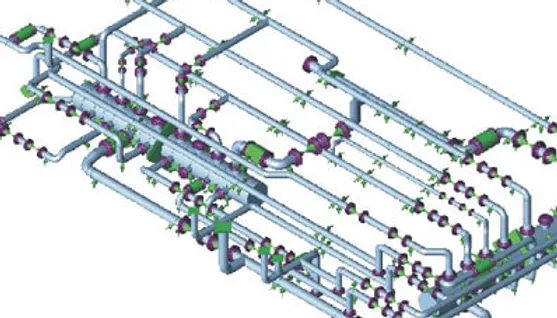

Why enroll

This course is the most comprehensive pipe stress analysis course available in the market. By joining this course you will be able to learn all the basic concepts of pipe stress analysis. The participant will be able to learn the use of Caesar II software. All the examples used in Caesar II modeling and analysis are from actual projects, so you will have an actual understanding of the job that you will be performing in live projects.

Finally, by digesting the contents delivered through the modules you will be able to improve your skill to such an extent that you will be easily employable by various reputed organizations. Also, if you are looking for a job change, the job-hunting process will be easier for you.

Opportunities that awaits you!

Earn a course completion certificate

Add this credential to your LinkedIn profile, resume, or CV. Share it on social media and in your performance review

Course content

The course is readily available, allowing learners to start and complete it at their own pace.

Online Course on Comprehensive Pipe Stress Analysis using Caesar II Software- Basics to Advanced

28 Lectures

1541 min

Part-A: What is Pipe Stress Analysis?

Preview

57 min

Part-A: Bonus Lecture: Introduction to Pipe Stress

63 min

Part-A: Bonus Lecture: Pressure Stresses in Piping

11 min

Part B: Bonus-Large Storage Tank nozzle evaluation on CaesarII based on API650

38 min

Part B: Pump Piping Stress Analysis Part 1

126 min

Part B: Pump Piping Stress Analysis-Part 2

88 min

Part B: Pump Piping Stress Analysis-Part 3

129 min

Part B: Pump Piping Stress Analysis-Part 4

114 min

Part B: Pump Piping Stress Analysis-Final Part

89 min

Part B: API610 Pump nozzle evaluation using CaesarII

16 min

Part D: Jacketed Piping Stress Analysis

51 min

Part D: Create Unit and configuration file in CAESAR II

10 min

Part D: ASME B31J for improved Method for i, k Calculation in Caesar II

37 min

Part D: Discussion about certain question and answers on pipe stress analysis

82 min

Part D: Questions and Answers

58 min

Part D: Questions and Answers-Final Part

55 min

Part D: GRE Stress Envelope-Part1

23 min

Part D: GRE Stress Envelope-Part2

23 min

Part D: GRE Stress Envelope-Final Part

28 min

Part D: An Overview of Pipe Stress Analysis-A detailed study

258 min

Part D: Additional Resources-Material Stresses in Piping

7 min

Part D: Additional Resources-Radial Stresses in Piping

8 min

Part D: Additional Resources-Forces and Moments in Piping

6 min

Part D: Additional Resources: Stress vs Strain

8 min

Part D: Additional Resources-Mohr's Circle & Principle Stresses

10 min

Part D: Additional Resources-Secrets Behind Caesar II-Theory and Calculations

16 min

Certain basics of HDPE Pipe Stress Analysis

105 min

Trunnion Support Design in Caesar II

25 min

Some More useful Resources

20 Lectures

620 min

Fiberglass and Steel Piping: Differences in Engineering

75 min

PIPING SPRING HANGER CONCEPT

37 min

Types of Pipe Stresses

79 min

Stress Intensification Factor (SIF) & Sustained Stress Index (SSI)

46 min

Air Cooler Modeling on Caesar II

10 min

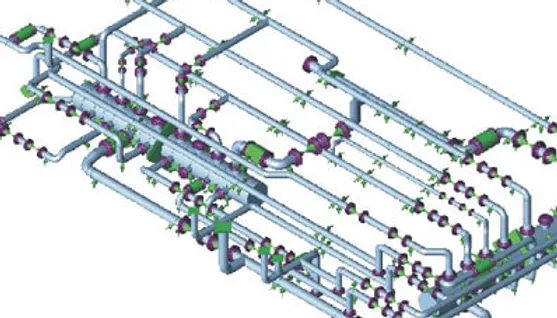

Pump Station Piping Design and Stress Analysis

9 min

A brief about Reboiler Piping Stress Analysis

7 min

Gas Outlet Piping Stress Analysis

8 min

Air-Cooled Heat Exchanger Piping

9 min

Solving vibration problems in a two-phase flowline

82 min

Analysis of Surge Problems with CAESAR-II and BOS-fluids

62 min

Integration for Productivity with CAESAR II & CADWorx

53 min

CAESAR II UNDERGROUND PIPE STRESS ANALYSIS

32 min

Flange calculations according to EN 1591-1

61 min

Spring Supports in Piping Design

11 min

Mechanism of variable spring hanger

4 min

Mechanism of constant spring hanger

5 min

How to install Spring Support at site

7 min

How to select spring hanger - for piping engineers

14 min

Internals of variable spring hanger

9 min

Course details

Please note that due to certain technical problems, the course is renamed and full content is moved to a new link as follows: https://www.everyeng.com/learn/96aa8069/advanced-pipe-stress-analysis-for-beginners-layout-materials-and-construction-professionals

Whoever had enrolled in this course has already given access to the above new link. Kindly check at your end and confirm.

The main objective of this course is to help you upgrade your knowledge to such an extent that you can feel yourself as an advanced pipe stress engineer. This course will cover all the basic concepts, and theories, in a simple way. The course will be divided into 4 parts.

Part A will cover the basic theories that are required to analyze stress systems using software programs. This section will prepare you to work as a pipe stress engineer.

Part B will cover the static analysis methodologies of the piping system in Caesar II software. This section will explain various modeling techniques, analysis methodologies, nozzle load qualification, and other required details.

Part C will cover the dynamic analysis philosophies and explain some of the dynamic modules of Caesar II.

Part D will explain some other details that are required for becoming an advanced pipe stress engineer.

So, overall, the course will cover the maximum of the pipe stress analysis methodologies in great extent. Please be patient as the course is going to be very long as it will clear most of your doubts. Even it will prepare you for your upcoming interviews by answering some of the questions.

Additionally, All participants will get 2-hours of doubt clearing session directly with the mentor.

Course suitable for

Oil & Gas Chemical & Pharmaceutical Energy & Utilities Mechanical Piping & Layout

Key topics covered

Please note that due to certain technical problems, the course is renamed and full content is moved to a new link as follows: https://www.everyeng.com/learn/96aa8069/advanced-pipe-stress-analysis-for-beginners-layout-materials-and-construction-professionals

Whoever had enrolled in this course has already given access to the above new link. Kindly check at your end and confirm.

Part A: Basics of Pipe Stress Analysis

What is Pipe Stress Analysis?

Stress Critical Line List Preparation with Practical Case Study

Inputs Required for Pipe Stress Analysis

Basics of ASME B31 3 for a Piping Stress Engineer

ASME B31.3 Scopes and Exclusions

Why stress is generated in a piping system

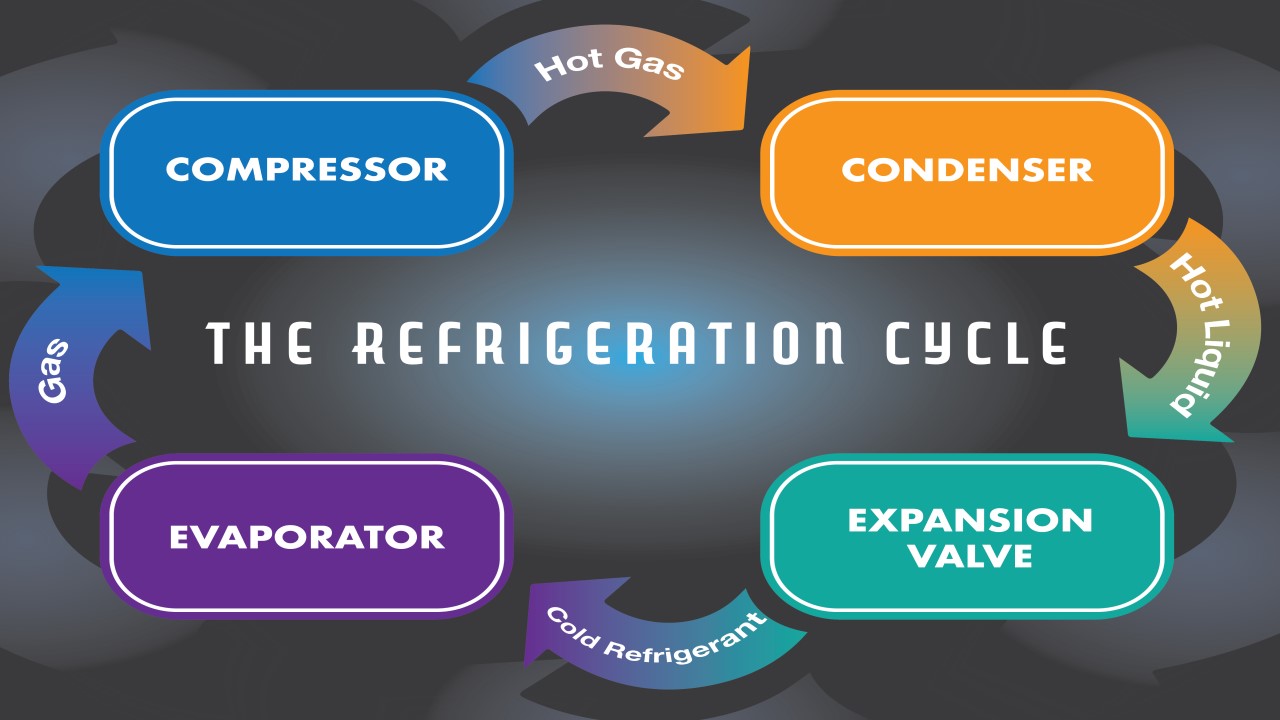

Types of Pipe Stresses

Pipe Thickness Calculation

Reinforcement Requirements

ASME B31.3 Code Equations and Allowables

Introduction to Pipe Supports

Role of Pipe Supports in Piping Design

Types of Pipe Supports

List of Pipe Supports

Pipe Support Span

How to Support a Pipe?

Pipe Support Optimization Rules

Pipe Support Standard

Support Engineering Considerations

What is a Piping Isometric?

What is an Expansion Loop?

Bonus Lecture: Introduction to Pipe Stress

Bonus Lecture: Pressure Stresses in Piping

Part-B: Static Analysis in Caesar II

Introduction to Caesar II

Getting Started in Caesar II

Stress Analysis of Pump Piping System

Creating Load Cases

Wind and Seismic Analysis

Generating Stress Analysis Reports

Editing Stress Analysis Model

Spring Hanger Selection and Design in Caesar II

Introduction

Types of Spring Hangers

Components of a Spring Hanger

Selection of Variable and Constant Spring hangers

Case Study of Spring Hanger Design and Selection

Certain Salient Points

Flange Leakage Analysis in Caesar II

Introduction

Types of Flange Leakage Analysis and Background Theory

Case Study-Pressure Equivalent Analysis

Case Study-NC Method

Case Study-ASME Sec VIII method

Stress Analysis of PSV Piping System

Introduction

PSV Reaction force Calculation

Applying PSV Reaction force

Practical Case Study

Certain best practices

Heat Exchanger Pipe Stress Analysis

Introduction

Creating Temperature Profile

Modeling the Heat Exchanger

Nozzle Load Qualification

Practical Case Study

Methodology for shell and tube inlet nozzle stress analysis

Vertical Tower Piping Stress Analysis

Introduction

Creating Temperature Profile

Equipment Modeling

Modeling Cleat Supports

Skirt temperature Calculation

Nozzle Load Qualification

Practical Example

Storage Tank Piping Stress Analysis

Introduction

Reason for Criticality of storage tank piping

Tank Settlement

Tank Bulging

Practical example of tank piping stress analysis

Nozzle Loading

Pump Piping Stress Analysis

API610 Pump nozzle evaluation using Caesar II

Part C: Dynamic Analysis is Caesar II

Introduction-Dynamic Analysis in Caesar II

Types of Dynamic Analysis

Static vs Dynamic Analysis

Dynamic Modal Analysis

Equivalent Static Slug Flow Analysis

Dynamic Response Spectrum Analysis

Part D: Miscellaneous other details

WRC 297/537 Calculation

What is WRC 537 and WRC 297

Inputs for WRC Calculation

WRC Calculation with Practical Example

Underground Pipe Stress Analysis

Jacketed Piping Stress Analysis

Create Unit and configuration file in CAESAR II

ASME B31J for improved Method for i, k Calculation in Caesar II

Discussion about certain Questions and Answers

GRE/FRP Pipe stress analysis

GRE Pipe Stress Analysis using Caesar II

GRE Stress Analysis-Basics

FRP Pipe Stress Analysis Case Study

GRE Flange leakage Analysis

Meaning of Stress Envelope; Understand it

Reviewing A Piping Stress System

Introduction

What to Review

Reviewing Steps

Case Study of Reviewing Pipe Stress Analysis Report

Reviewing Best Practices

FIV Study

Flow Induced Vibrations-Introduction

What is Flow Induced Vibration

Flow Induced Vibration Analysis

Corrective-Mitigation Options

AIV Study

Introduction

What is Acoustic Induced Vibration

Acoustic Induced Vibration Analysis

Corrective-Mitigation Options

2-hours of Doubt-clearing session with the mentor

Why people choose EveryEng

Industry-aligned courses, expert training, hands-on learning, recognized certifications, and job opportunities—all in a flexible and supportive environment.

- Industry Veteran

- Trainer Review

Anup Kumar Dey

Owner of https://whatispiping.com/

Questions and Answers

No questions yet - Be the first one to ask!

More from Same Author

- Technical Courses

- Articles

644

Online

Live courses

April 24

30 Hrs

Advanced

Online

Live courses

Interacting with trainer

777

Online

Live courses

June 30

45 Hrs

Advanced

Online

Live courses

Interacting with trainer

670

3

Online

Live courses

March 15

10 Hrs

Advanced

Online

Live courses

Interacting with trainer

Earning and Growth option in same Industry Domain

- Pre-recorded

- Online live session

- Offline

- Articles

5627

81

E-Learning

Unlimited access

E-Learning

Unlimited access

Pre-recorded videos

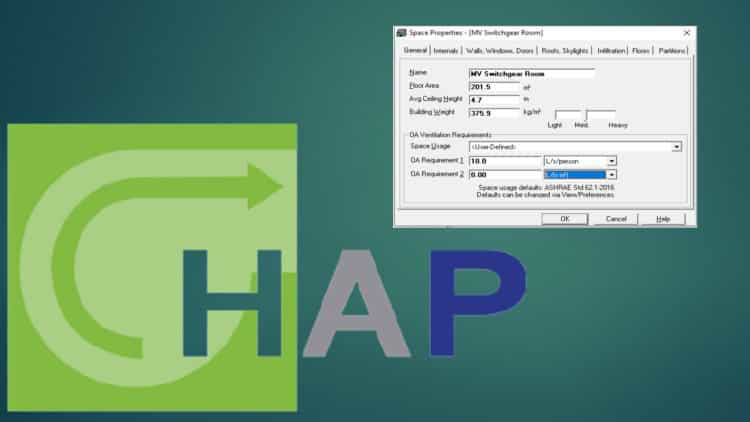

Md Firan Mondal

Lead HVAC Engineer | CEng, MIMechE, UK I CEng, KIVI, Europe I B.E (Mechanical) I Oil & Gas I HVAC Wind Platforms I Green Hydrogen I Blogger

$10

1022

1

E-Learning

Unlimited access

Intermediate

E-Learning

Unlimited access

Pre-recorded videos

9943

7

E-Learning

Unlimited access

Advanced

E-Learning

Unlimited access

Pre-recorded videos

Md Firan Mondal

Lead HVAC Engineer | CEng, MIMechE, UK I CEng, KIVI, Europe I B.E (Mechanical) I Oil & Gas I HVAC Wind Platforms I Green Hydrogen I Blogger

$800

More Training & Development option to expand your reach

- Technical courses

- Soft-skills courses

- Seminars

- Articles & Blogs

1555

5

Online

Live courses

December 31

160 Hrs

Advanced

Online

Live courses

Interacting with trainer

72

Online

Live courses

February 1

3 Hrs

Beginner

Online

Live courses

Interacting with trainer

590

Online

Live courses

February 21

30 Hrs

Advanced

Online

Live courses

Interacting with trainer